Limatherm S.A. offers comprehensive services for foundry projects, from the initial stage to assistance with certification of the final product, which includes:

Limatherm takes full responsibility for the life of the mould and the quality of the parts produced.

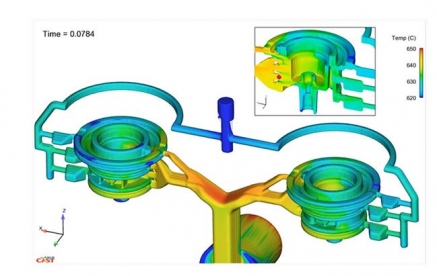

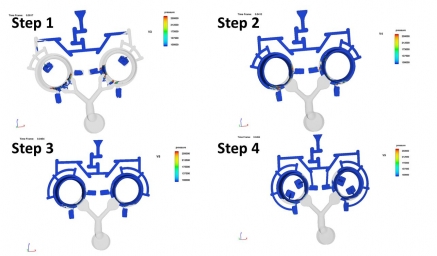

The simulation of the mould filling verifies the process assumptions. If the part has not been produced in series before, it is very important to adapt its shape to the die casting technology. Wall thicknesses, radii or reproduced shapes should be designed in the most optimal way for the process to avoid quality problems and fast tool wear. Limatherm has extensive experience in this field and offers you full technical support.

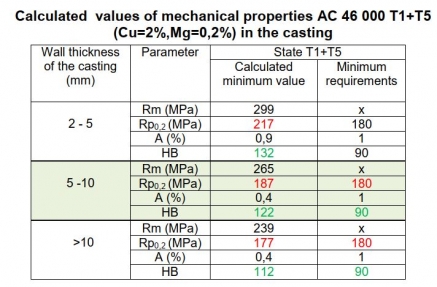

Limatherm carries out innovative projects with cast alloys including T1 + T5 heat treatment. We are testing the strength of EN AC-46000 alloy after heat treatment.